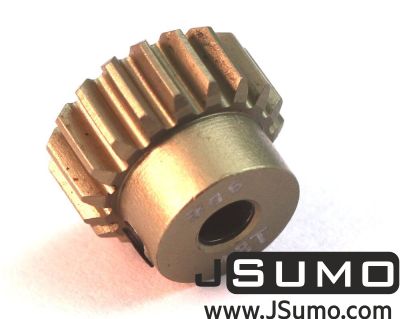

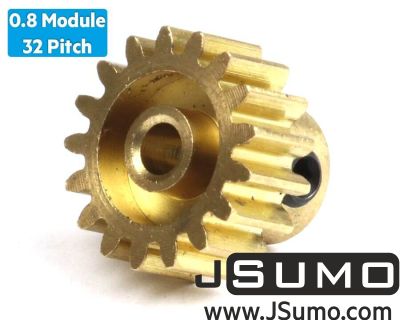

Gears are generally used to reduce speed and increase torque. They can be produced from many different materials.The gears on our JSumo site are generally preferred for sumo robot projects and similar robotics projects. We have gears in stock from 0.4 Module to 1 Module. With bigger module number gear strength and dimensions incrases, with smaller module numbers dimensions, tooth distances decrases. We suggest 0.8 - 1.0 module gears for though projects, but if project needs presice movement we suggest 0.6, 0.5 and 0.4 module gears.

Gears of the same module must be used together (0.8 module, 0.8 module). Otherwise it will be incompatible. In addition, some modular gears between the metric system and the imperial system are available in both standards (such as 0.8 Module - 32 Pitch). In the product names, the pitch equivalent of the gears is given in parentheses (imperial).

Pinion gears (usually small gears that are first driven by the shaft) come with setscrews. Only this setscrew should be slightly tightened with an allen key. Tightening it too hard can damage the set screw, and even crack/break the weak body in thin-walled gears (such as 0.8 module 13T). For this reason, we always recommend using a light tightening with a setscrew and using an additional bolt adhesive for pinions.

Moreover, in the pinion gear assembly, the motor shaft must be processed a little to make it a flat surface (for example, 1 mm flattening for a 6mm shaft) and then the setscrew connection part will be here to make the connection healthier.

Custom Gear Machining?

Please contact us we can machine small modules from 0.4 module to 2 module gears with light and hardened steel materials. Any tooth number can be machined.

Arduino

Arduino Boards

Boards Components

Components Ebooks

Ebooks Magnet

Magnet Mechanics

Mechanics Motors

Motors Drone

Drone Power

Power Robot Bodies (Chassis)

Robot Bodies (Chassis) Robot Kits

Robot Kits Sensors

Sensors Tools

Tools Wheels

Wheels